The Project

The Mousa Residence represents a unique Architectural design for the North Queensland region as it incorporates large expanses of glass flanked by green walls overlooking a deck, entertainment area and infinity pool.

The owners wanted to be able to create a bespoke residential dwelling with an open plan design allowing a seamless flow from inside to out with a heavy focus on the utilisation of large glass panels to facilitate this design. The clients approached JH Glass Innovation in the early stages of their design to provide insights and solutions to ensure they could achieve their end vision.

Part of the unique challenges of this project, was the client’s choice of a custom window and door manufactured by Sydney company (By Vincenzo) who produces award winning products. However, due to the North Queensland wind loadings (C3) the installation of this system in the North Queensland region required a custom solution.

Director John Hyde designed and developed a solution by engaging Polytron Glass Australia to produce custom panels of 21.52mm clear SG laminated safety glass which were then transported to Sydney to be glazed into the By Vincenzo window and door system. This system was then freighted to Cairns for installation by the JH Glass Innovation team while overseen by owner and Director of By Vincenco, who flew up to ensure the integrity of his system.

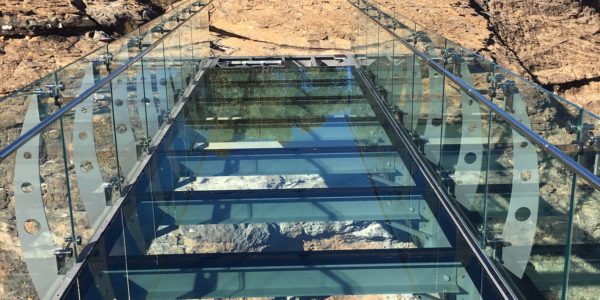

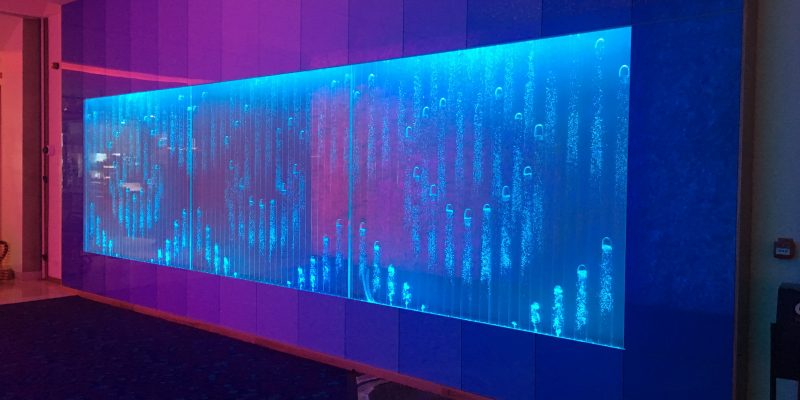

Other glass elements in this project included an 8m high glass curtain wall using spider fittings, custom made 2.7m high x 4m wide steel framed sliding doors incorporating 2.7m high x 2.4m wide pivot doors featuring a curved top element to enhance the design features as well as 3.5m wide automatic guillotine windows to each bedroom to capture the amazing views of Cairns as well as custom balustrading and pool fencing with underlit LED lighting in handrails and 2 large custom pool windows.

The end results exceeded the client’s vision and successfully demonstrated what can be achieved by the creative uses of glass in a complex North Queensland environment to create a seamlessly beautiful yet functional project.